Client

Mahaweli Authority of Sri Lanka

Division of Major Dams & Reservoir Operation – Kotmale Dam

Project Overview

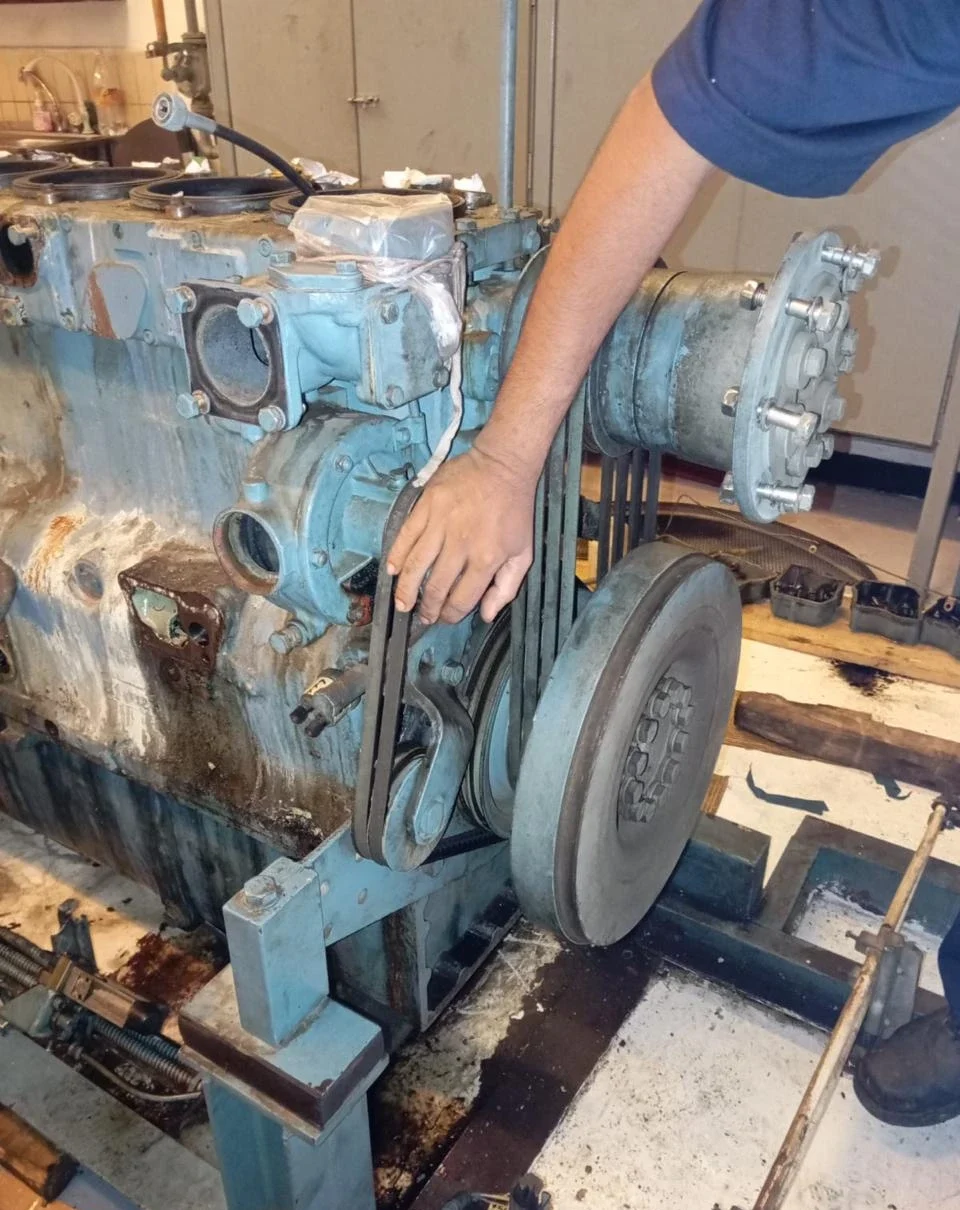

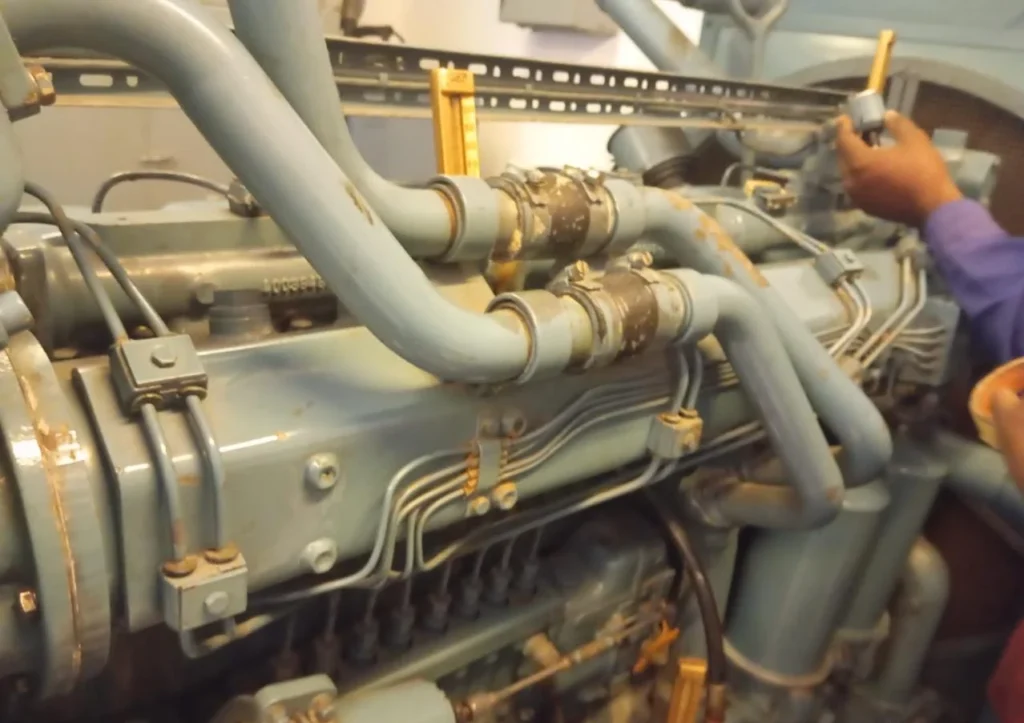

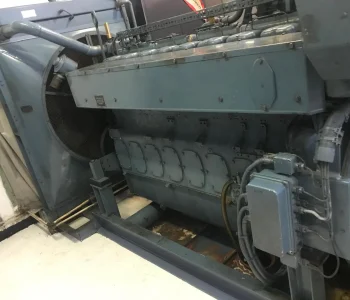

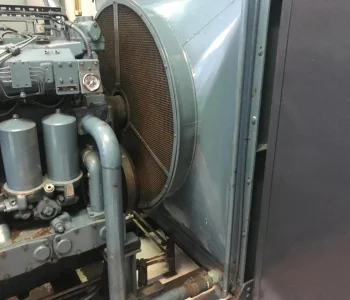

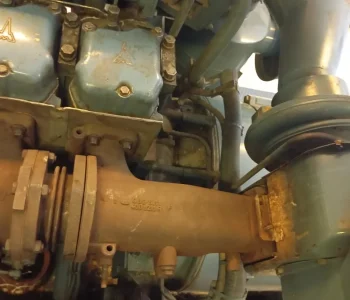

This report summarizes the inspection, analysis, and complete overhaul of the ASEA generator powered by a KHD DEUTZ BA8M816LKU engine, including full restoration of the generator’s automation and control system to its original operational standards.

The work was carried out under the supervision of the Mahaweli Authority of Sri Lanka, following operational complaints of coolant leakage, power instability, and intermittent control panel malfunctions.

An initial inspection and technical evaluation revealed multiple system faults, leading to the issue of a purchase order for a comprehensive repair program.

Initial Inspection Findings

- Cooling System Defects

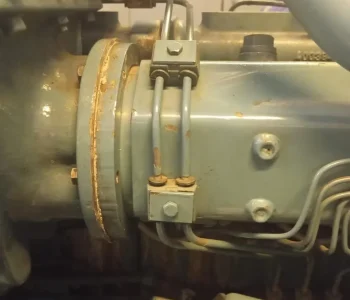

– Jacket water coolant leakage observed through several cylinder-head ferrules.

– Corrosion and scaling identified in the water jacket passages. - Lubrication & Mechanical Defects

– Oil leakage from sump and timing cover gaskets.

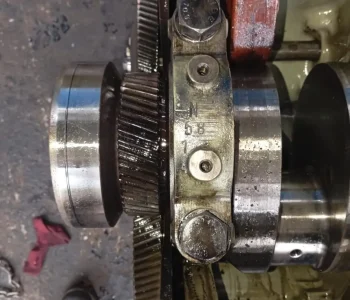

– Main bearings and connecting rod bearings heavily worn.

– Cylinder liners and piston rings showed severe wear and carbon accumulation. - Electrical and Alternator Condition

– Insulation failure on alternator windings with visible dust and oil contamination.

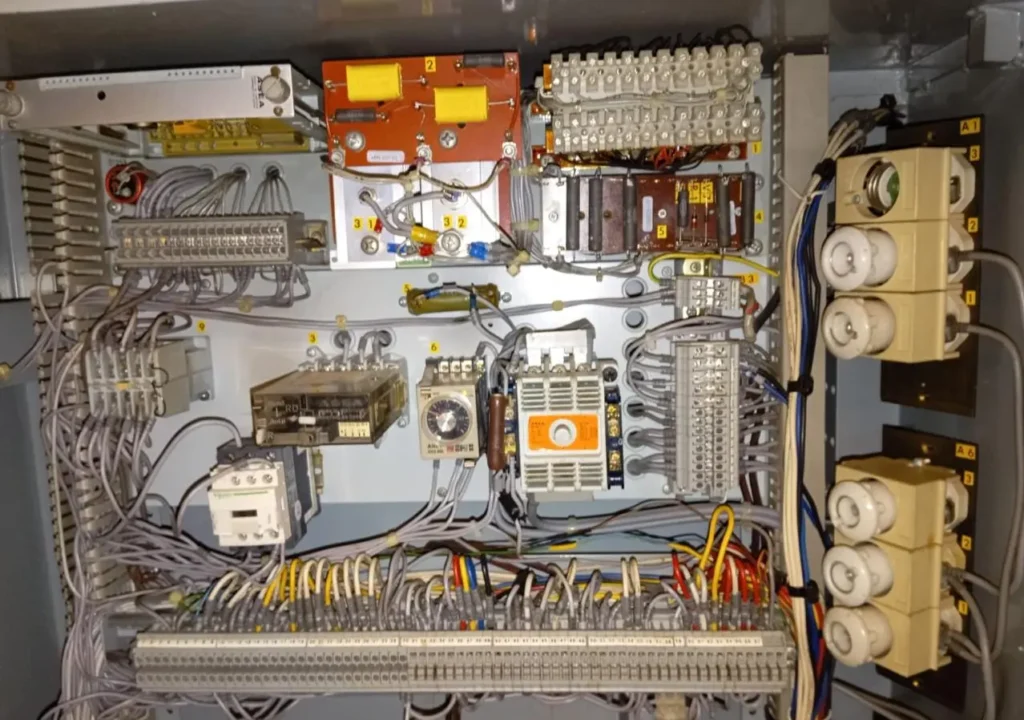

– Bearings in alternator found dry and near end-of-life. - Control and Automation Panel Issues

– Manual/Auto selector switch non-functional.

– Fault lamps, emergency stop, and safety trip relays partially inactive.

– Frequency and voltage meters displaying erratic readings.

– Alarm system and shutdown circuits required full rewiring and recalibration.

Generator & Engine Technical Details

Parameter

Generator Brand

Type

Capacity

Frequency

Voltage

Engine Brand

Model

Engine No.

Rated Power

Overload Power

Year of Manufacture

Total Running Hours

Details

ASEA – Sweden

DGRB 8M REF 16191010-4

415 kVA

50 Hz

400 V

KHD DEUTZ (Germany)

BA8M816LKU

6745669

358 kW @ 1500 rpm

394 kW @ 1490 rpm

1982

1,738 hours

Approval & Spare Part Procurement

Following the inspection, the Mahaweli Authority approved the complete repair and overhaul based on the findings.

Given the engine’s 1982 production year, sourcing genuine components posed significant challenges. Mermaid Solutions successfully leveraged its global presence in the United Kingdom and Canada to identify and import OEM-grade Deutz spare parts through the original manufacturer network.

Mechanical Overhaul

– Replaced all 8 cylinder liners and O-ring kits.

– Installed new main and connecting rod bearings.

– Replaced piston ring kits, shaft seals, and gaskets.

– Calibrated fuel injection pump and injectors with new nozzles.

– Chemically cleaned and pressure-tested the cylinder block and coolant passages.

Electrical & Alternator Works

– Full insulation improvement of alternator windings.

– Replaced alternator bearings and cleaned terminals.

– Serviced starter motor and charging alternator assemblies.

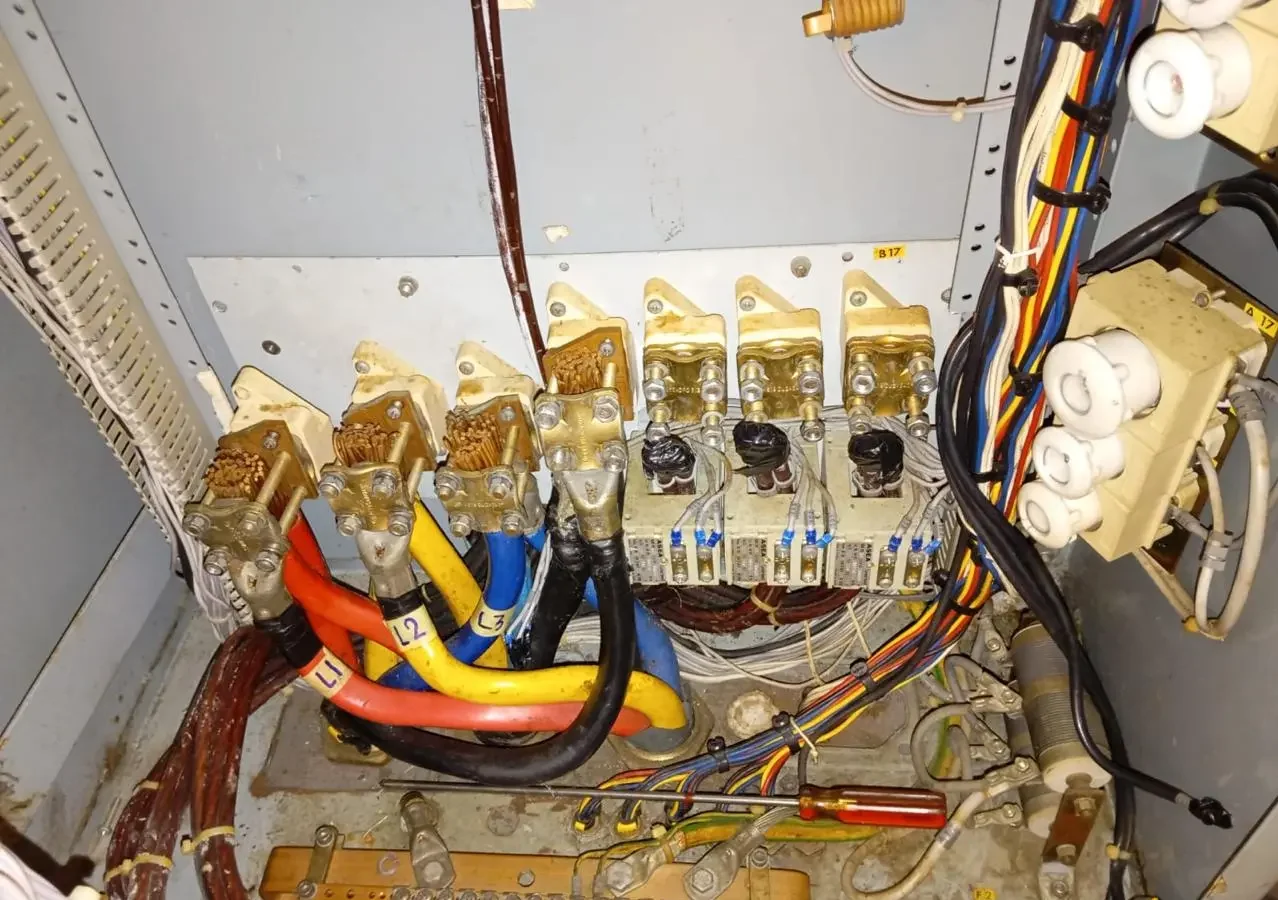

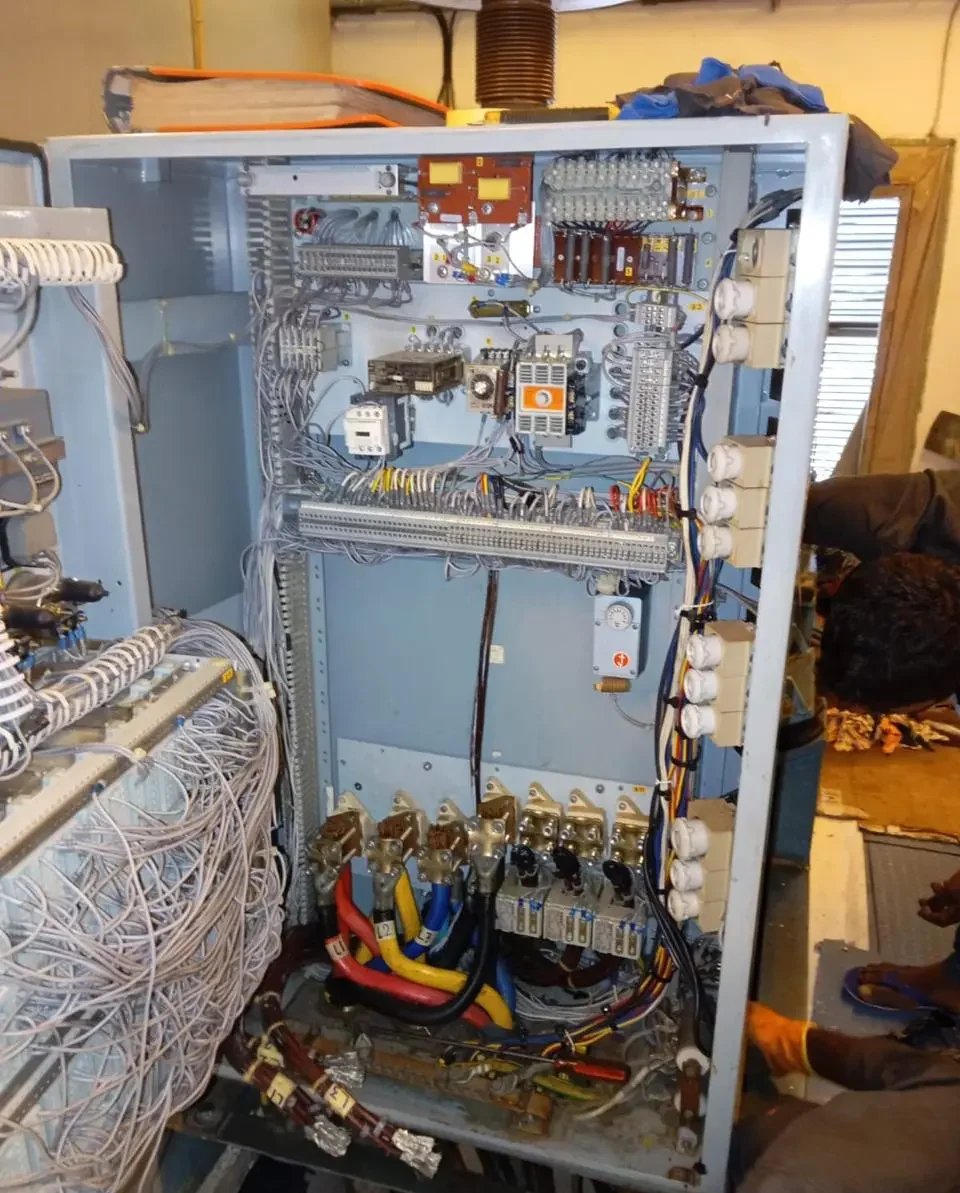

Control & Automation System Restoration

– Overhauled the entire generator control and automation system, including:

– Manual/Auto operation system.

– Frequency, voltage, and current monitoring instruments.

– Generator breaker controls, fault lamps, and safety shutdown relays.

– Glow plug circuit, emergency stop function, and protection alarms.

– All automation circuits recalibrated and tested to factory standards.

– The control panel was restored to its original operational configuration, ensuring reliable automatic and manual start/stop sequences.

Work Scope Executed

Completion Status

The complete overhaul of the Deutz BA8M816LKU engine and ASEA generator system was successfully executed by Mermaid Solutions Pvt Ltd, restoring both the mechanical integrity and automation control functionality of the system.

The unit was tested, calibrated, and recommissioned on 04th October 2025, with all alarm and shutdown parameters verified under operational load.

Conclusion

This project demonstrates Mermaid Solutions Pvt Ltd’s expertise in complete engine, generator, and automation system restoration for legacy European power units.

Despite the challenges posed by the engine’s age and obsolete control components, the generator system was successfully returned to full operational reliability and safety compliance, maintaining original Deutz and ASEA performance standards.

Contact

Mermaid Solutions Pvt Ltd

No. 73, MJC Fernando Mawatha, Idama, Moratuwa, Sri Lanka

Email: info@mermaidsolution.com

Tel: 94 71 658 5745

Mr. Sachintha Rathnayake

Engineer – Division of Major Dams & Reservoir Operation

Mahaweli Authority of Sri Lanka – Kotmale Dam

Tel: +94 71 658 5745