Client

ITC Hotel, Colombo

Consultant

Mr. Siva Kumar, ITC Group

Location

Fire Pump Room, ITC Building – Colombo 01

Date of Completion

September 2024

Executed by

Mermaid Solutions Pvt Ltd

Project Background

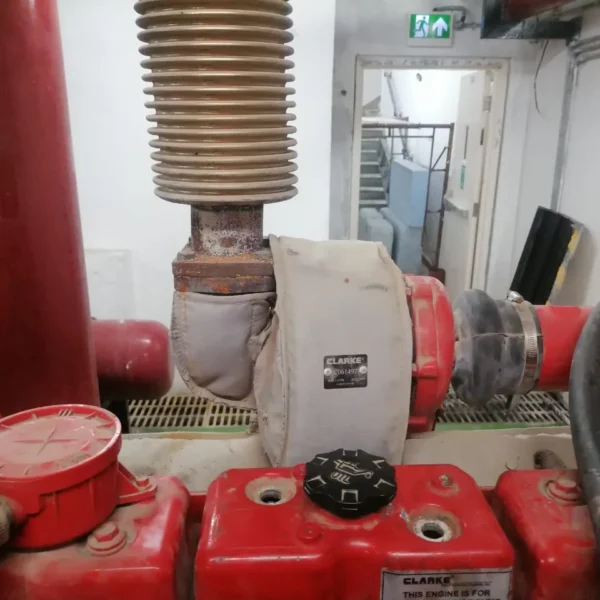

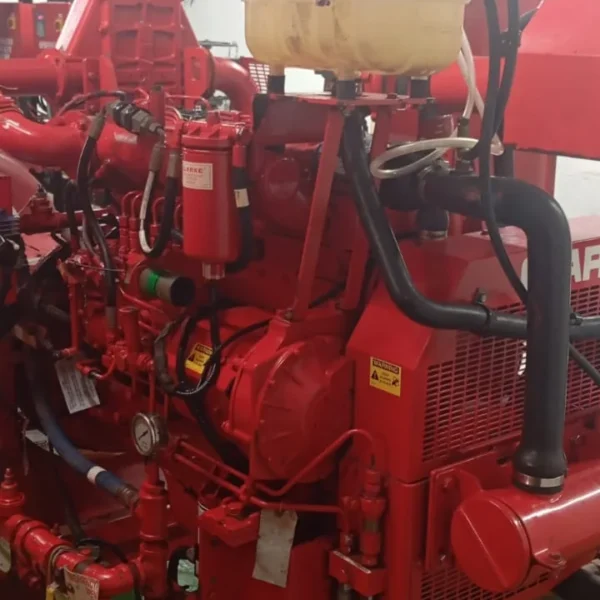

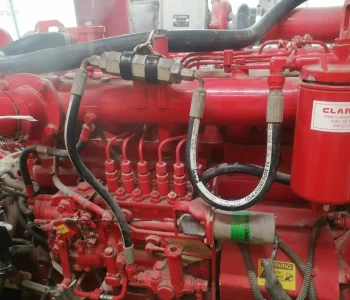

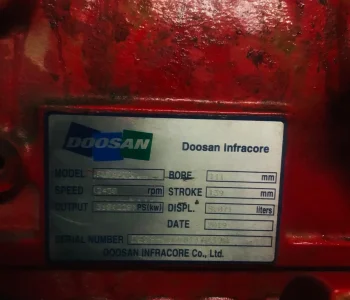

Based on the approval received from ITC Hotel Management, Mermaid Solutions Pvt Ltd was assigned to carry out the complete engine overhaul of the Doosan Infracore Diesel Engine coupled to the Clarke Fire Pump System. The task was initiated following a major defect caused by rainwater entering through the exhaust manifold, which led to engine flooding and oil dilution.

This was the first project undertaken by Mermaid Solutions Pvt Ltd for the ITC Group, and it marked the beginning of a long-term partnership between both organizations.

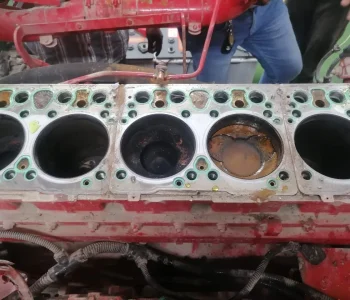

Root Cause Analysis

Inspection revealed that rainwater had entered through the open exhaust system during idle conditions. The presence of water in the cylinders caused water hammering, which led to significant internal mechanical stress. The issue was worsened when the engine was started by an unauthorized person without checking the oil condition, resulting in bearing surface wear, lubrication failure, and piston damage.

Overhaul Procedure

Following the formal approval from ITC Hotel Management, Mermaid Solutions Pvt Ltd executed a comprehensive overhaul of the Doosan Infracore diesel engine powering the Clarke fire pump system. All works were completed in strict accordance with the manufacturer’s specifications and NFPA 20 standards for stationary fire pump engines.

A) Dismantling & Inspection Phase

- Engine Disassembly:

• Disconnected all auxiliary systems including cooling, fuel, exhaust, and lubrication circuits.

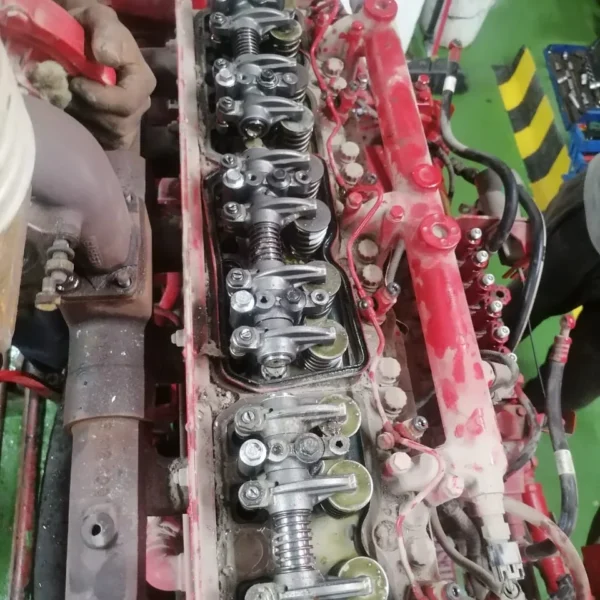

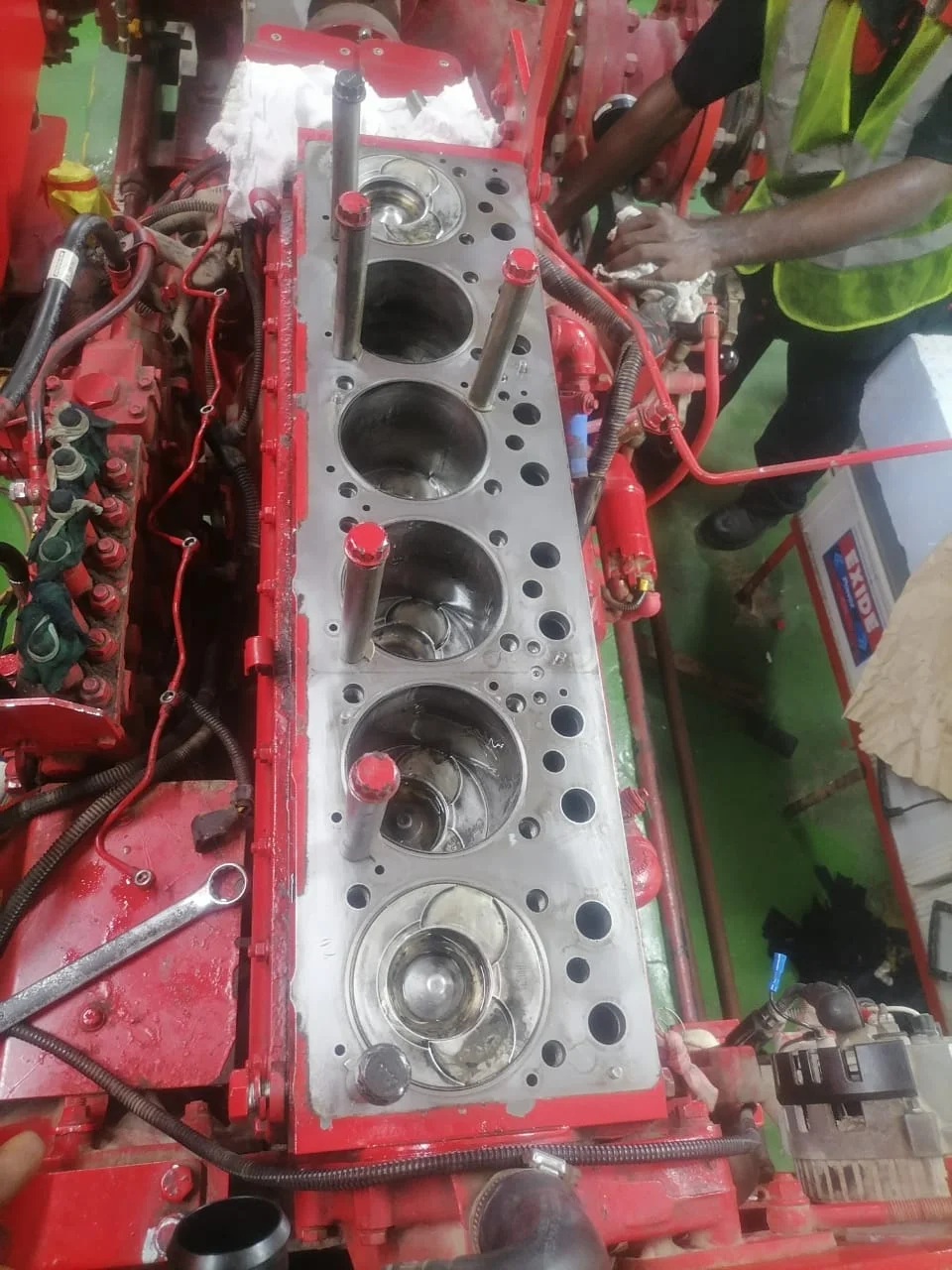

• Removed cylinder head, pistons, liners, crankshaft, and all accessories for complete visual and dimensional inspection.

• Isolated and drained contaminated lubricating oil and flushed sump to remove emulsified deposits. - Preliminary Inspection:

• Detected severe moisture contamination and surface rust within the cylinder liners and combustion chambers.

• Found multiple bearings with surface scoring due to lubrication breakdown.

• Verified evidence of water hammering through piston crown deformation and connecting rod stress marks.

B) Non-Destructive & Dimensional Testing

- NDT Examinations:

• Magnetic Particle Testing (MPT) and Dye Penetrant Testing (DPT) conducted on:

• Crankshaft journals and fillets.

• Connecting rods (big-end and small-end).

• Cylinder block and head surfaces.

• No critical cracks found, confirming structural integrity - Dimensional Measurements:

• Crankshaft deflection within OEM tolerance (0.05 mm).

• Connecting rod bending and twisting verified and recorded.

• Cylinder liner inner diameter, taper, and ovality checked using bore gauge.

• Piston ring end gaps and bearing clearances re-measured and documented.

C) Component Replacement & Reconditioning

- To ensure reliability and restore original factory tolerances, the following major components were renewed:

• Main bearings and connecting rod bearings.

• Pistons and piston rings (Doosan genuine parts).

• Full gasket set, O-rings, and oil seals.

• Lubricating oil filters and fuel filters.

• Engine oil (SAE 15W-40 API CI-4 grade).

• Coolant flushed and renewed with 50% glycol-based inhibitor solution.

Additionally, the cylinder head valves and seats were lapped, injector nozzles serviced, and the fuel injection pump recalibrated.

D) Reassembly & Calibration

• All assemblies torqued to OEM specification using calibrated torque wrenches.

• Valve tappet clearances and fuel timing set as per Doosan service manual.

• New belts, hoses, and mounting fasteners installed.

• Oil pressure switch, temperature sender, and control sensors tested for correct readings.

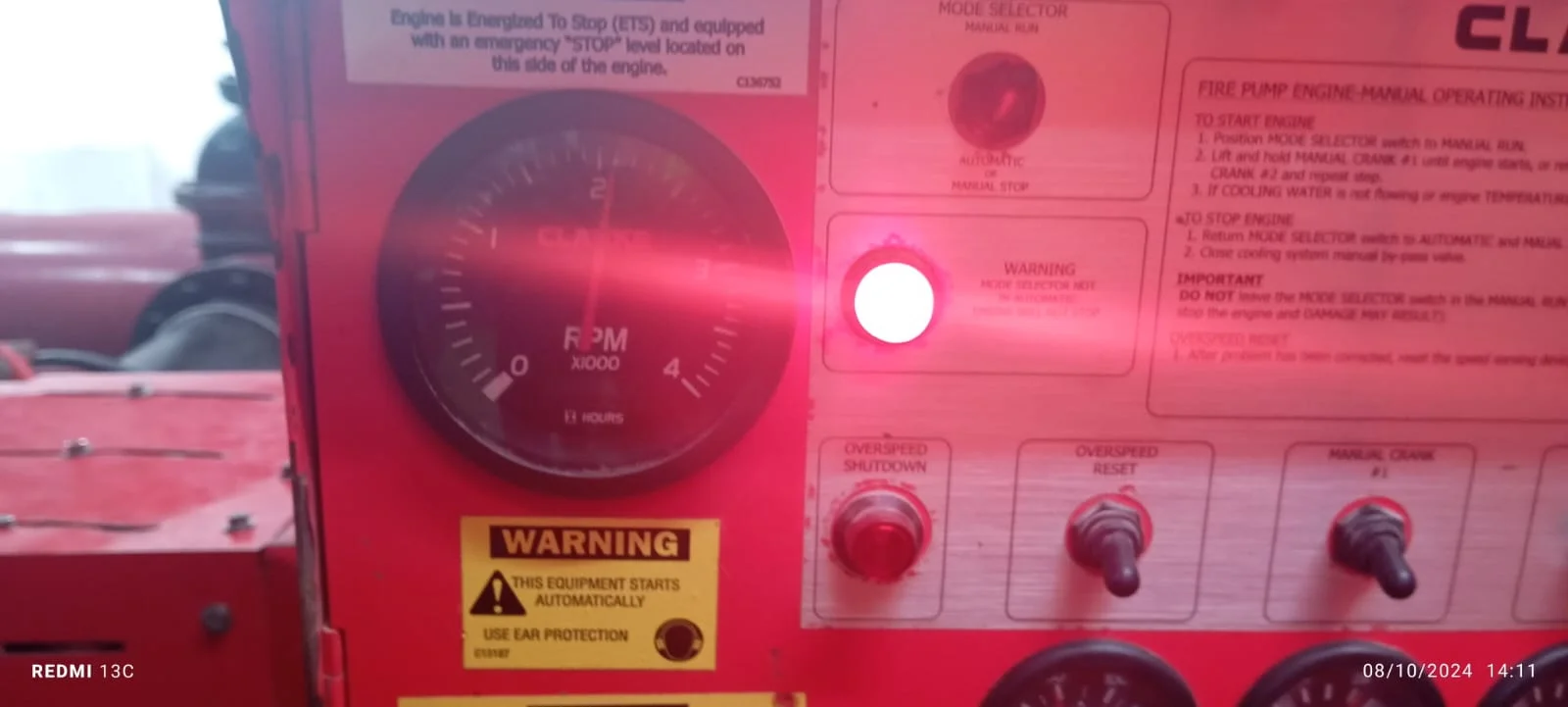

E) Testing & Commissioning

- Initial Dry Run:

• Engine cranked without fuel to establish oil pressure and verify priming. - Load Testing:

• Fire pump performance tested at rated discharge pressure.

• Engine parameters recorded: oil pressure, coolant temperature, RPM stability, vibration, and exhaust color - Final Verification:

• Automation and control system checked for alarm and shutdown response.

• Cooling system pressure and exhaust gas temperature monitored for 1-hour operational cycle.

F) Report & Handover

- A full set of test results, torque values, and replaced part details were documented.

The engine was handed over to ITC Hotel Maintenance Department in fully operational condition, with recommendations for routine maintenance and exhaust weather protection.

Supervision & Client Involvement

The entire overhaul process was carried out under the direct technical supervision of Mr. Siva Kumar, Consultant – ITC Group, who has many years of experience in facility engineering and maintenance.

Mr. Kumar thoroughly inspected and guided each step of the repair procedure to ensure strict adherence to ITC’s operational standards. His valuable technical guidance and recommendations ensured that the engine was restored to its original factory performance level.

The ITC Group is a prestigious and globally recognized conglomerate, operating across hospitality, FMCG, infrastructure, and energy sectors. The ITC Hotel division is renowned for excellence in operational reliability, sustainability, and engineering performance.

This project, being the first collaboration between Mermaid Solutions and ITC Group, was executed successfully and laid the foundation for multiple future maintenance and service projects handled by Mermaid Solutions Pvt Ltd. Our company remains the trusted service partner for ITC Group, continuing to provide maintenance, overhaul, and system support for their critical fire pump and engine systems.

Project Significance & Partnership

Completion Status

All works were completed successfully within the approved time frame, and the fire pump engine is now fully operational and compliant with OEM standards. Post-overhaul testing confirmed stable performance parameters under full load conditions.

Contact

Mermaid Solutions Pvt Ltd

No. 73, MJC Fernando Mawatha, Idama, Moratuwa, Sri Lanka

Email: info@mermaidsolution.com

Tel: +94 11 2332323